-

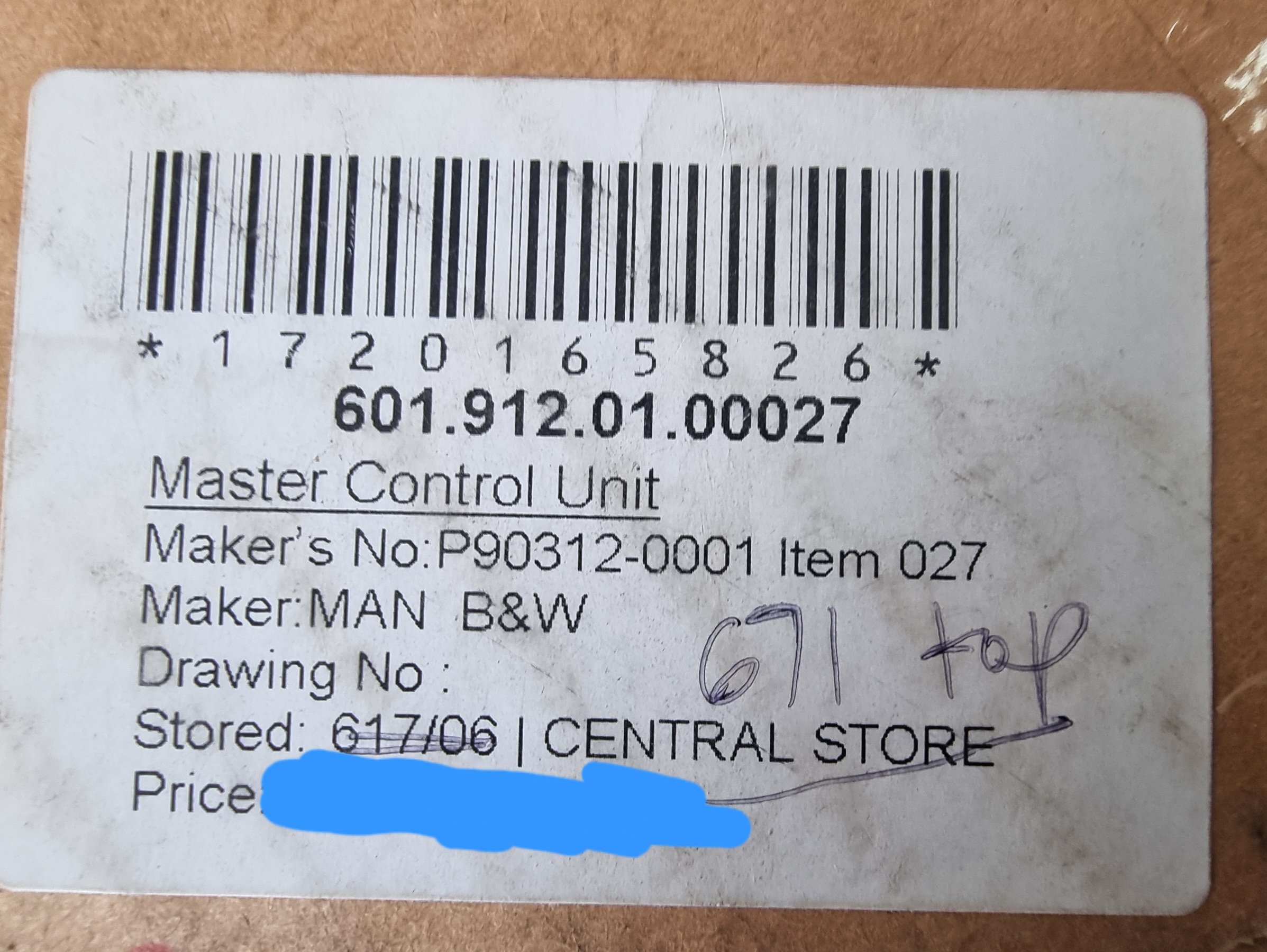

MAN B&W: This is the manufacturer. MAN B&W is a world-leading German manufacturer of large two-stroke diesel engines, primarily used for main propulsion on large commercial ships like container vessels, tankers, and bulk carriers.

-

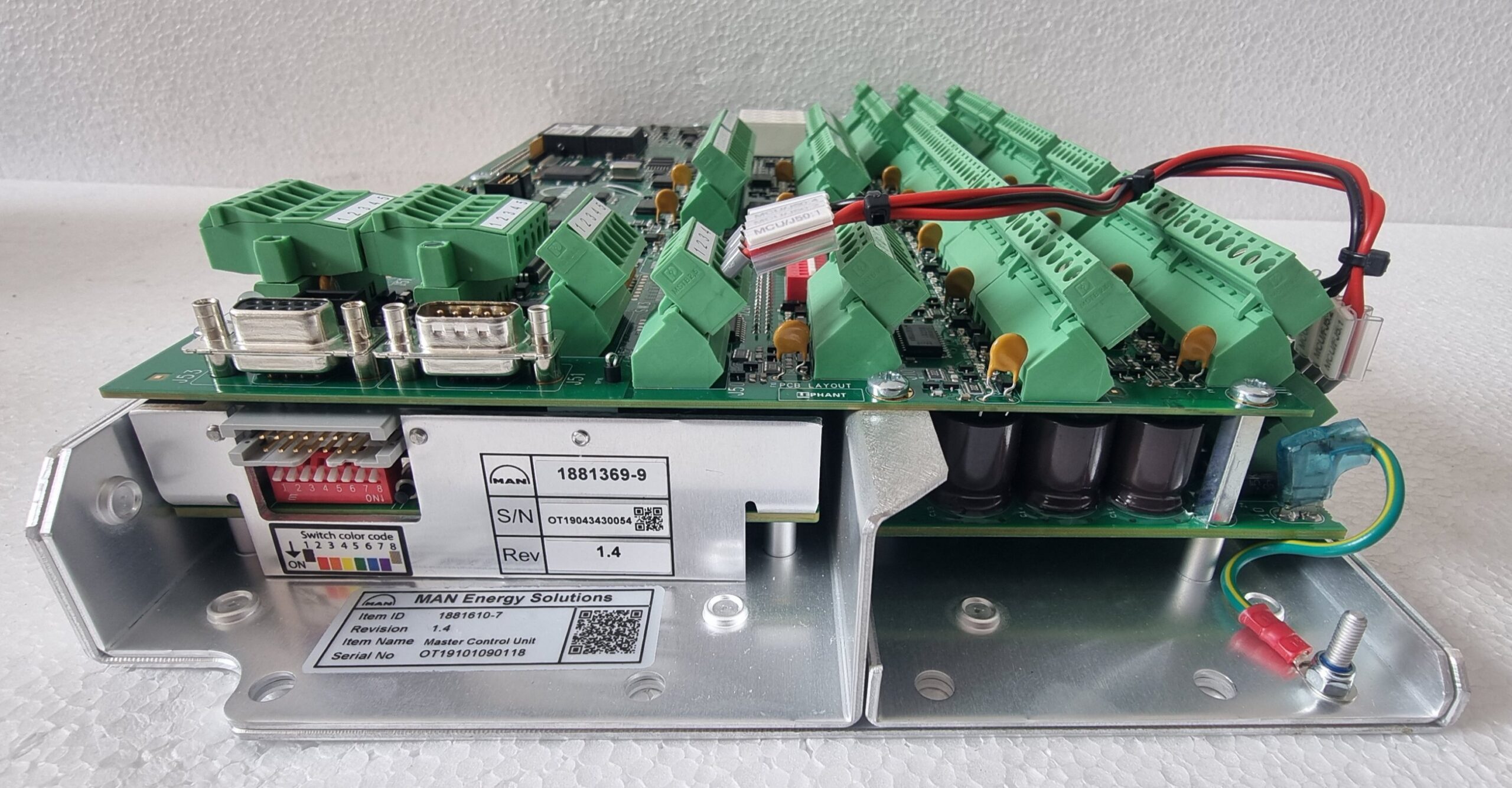

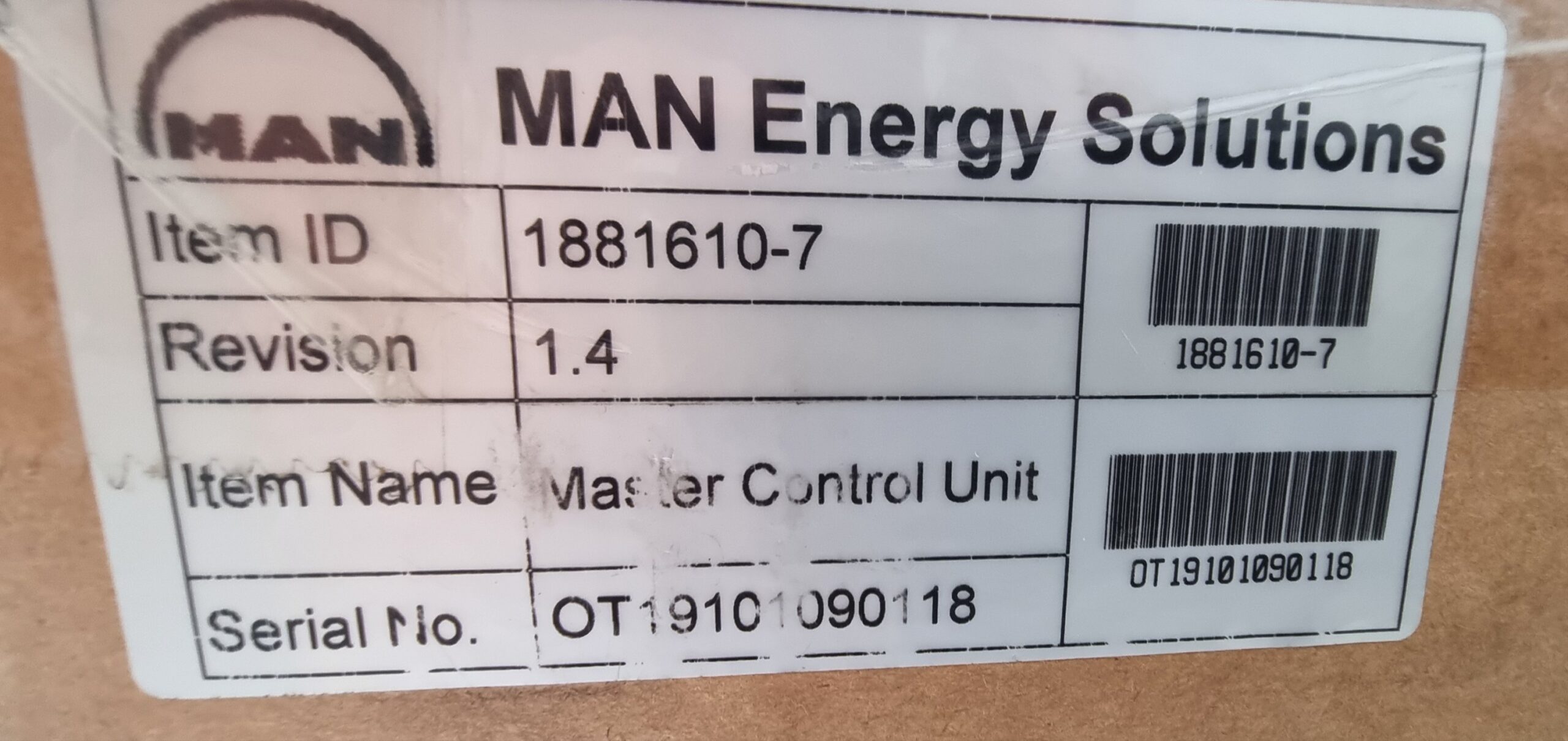

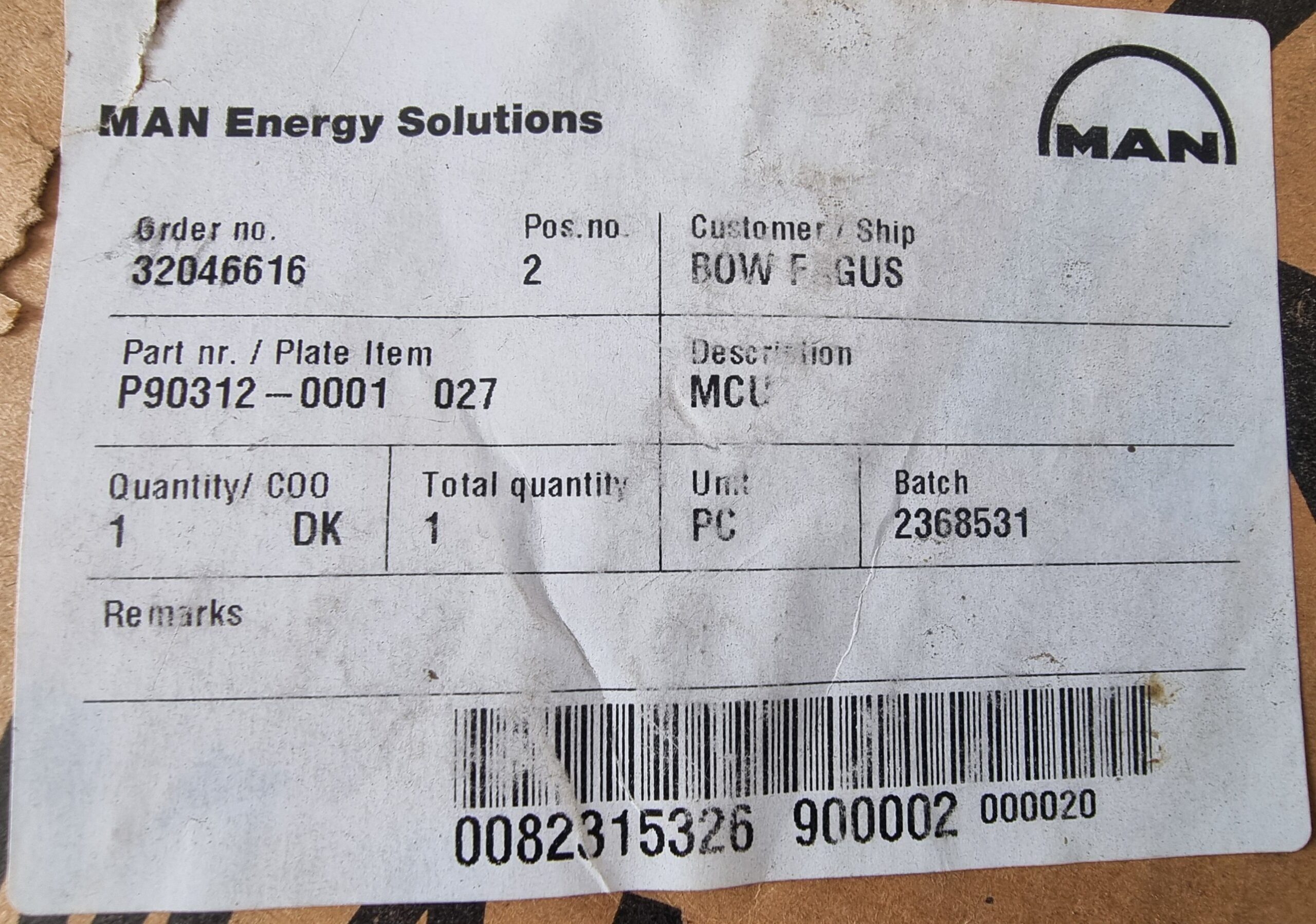

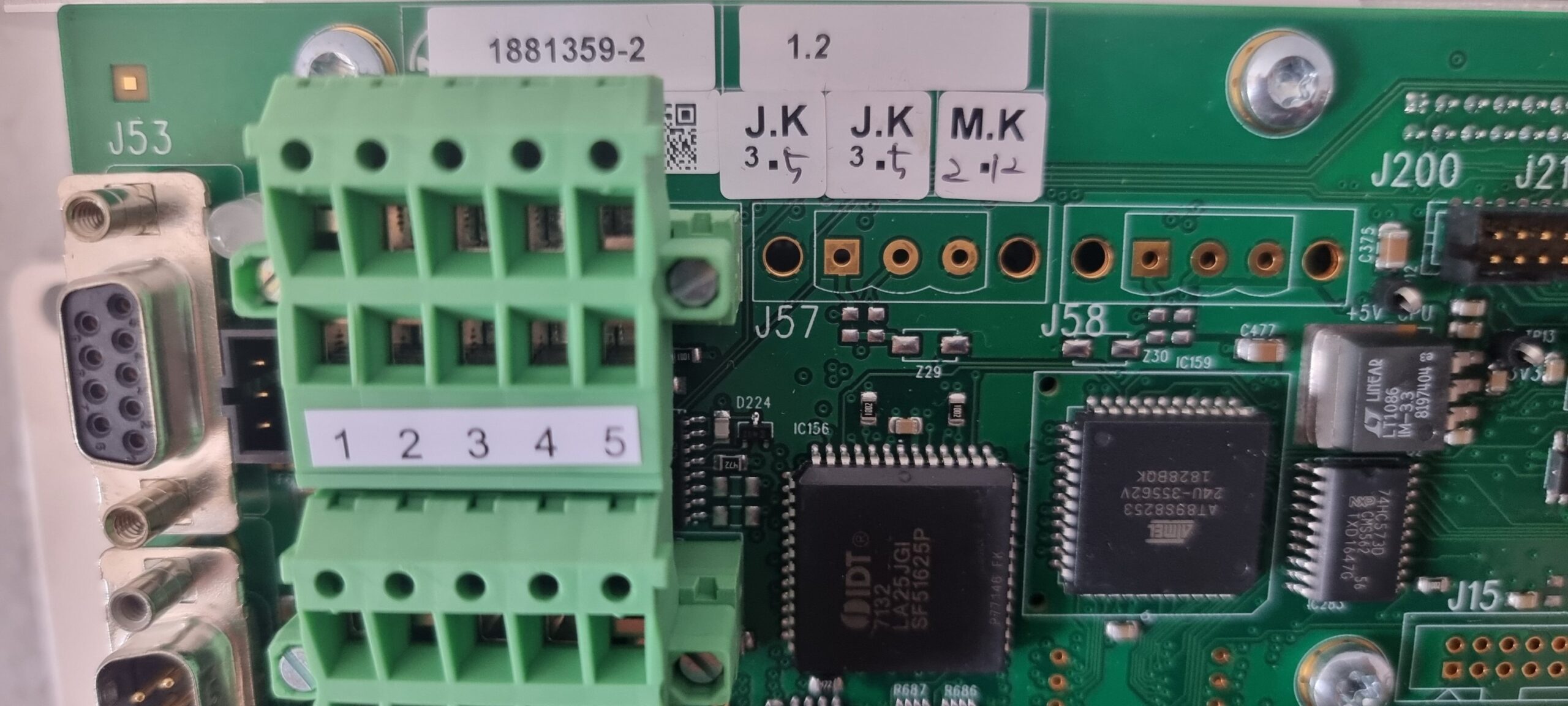

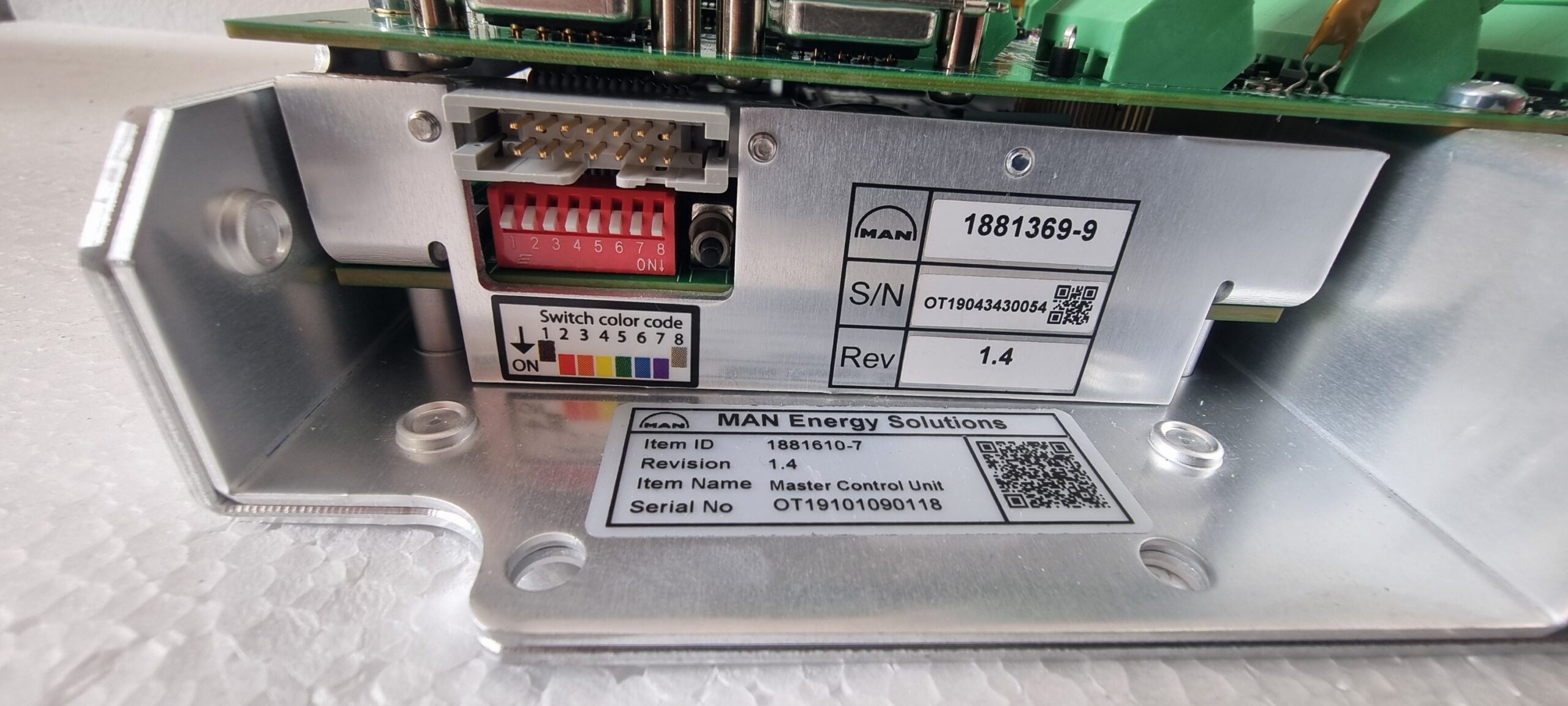

1881610-7: This is the unique Part Number or Article Number. This specific sequence identifies this exact printed circuit board (PCB) among thousands of other parts. The “-7” is often a suffix denoting a specific variant or version within the same part family.

-

REV 1.4: This stands for Revision 1.4. It indicates this is the 4th iteration of the design for this specific PCB. Revisions are made to fix bugs, improve reliability, or incorporate new features. It is crucial to use the correct revision specified by the engine manufacturer to ensure compatibility and proper operation.

-

MASTER CONTROL UNIT: This is the functional name of the component. This is the most important part of the description.

-

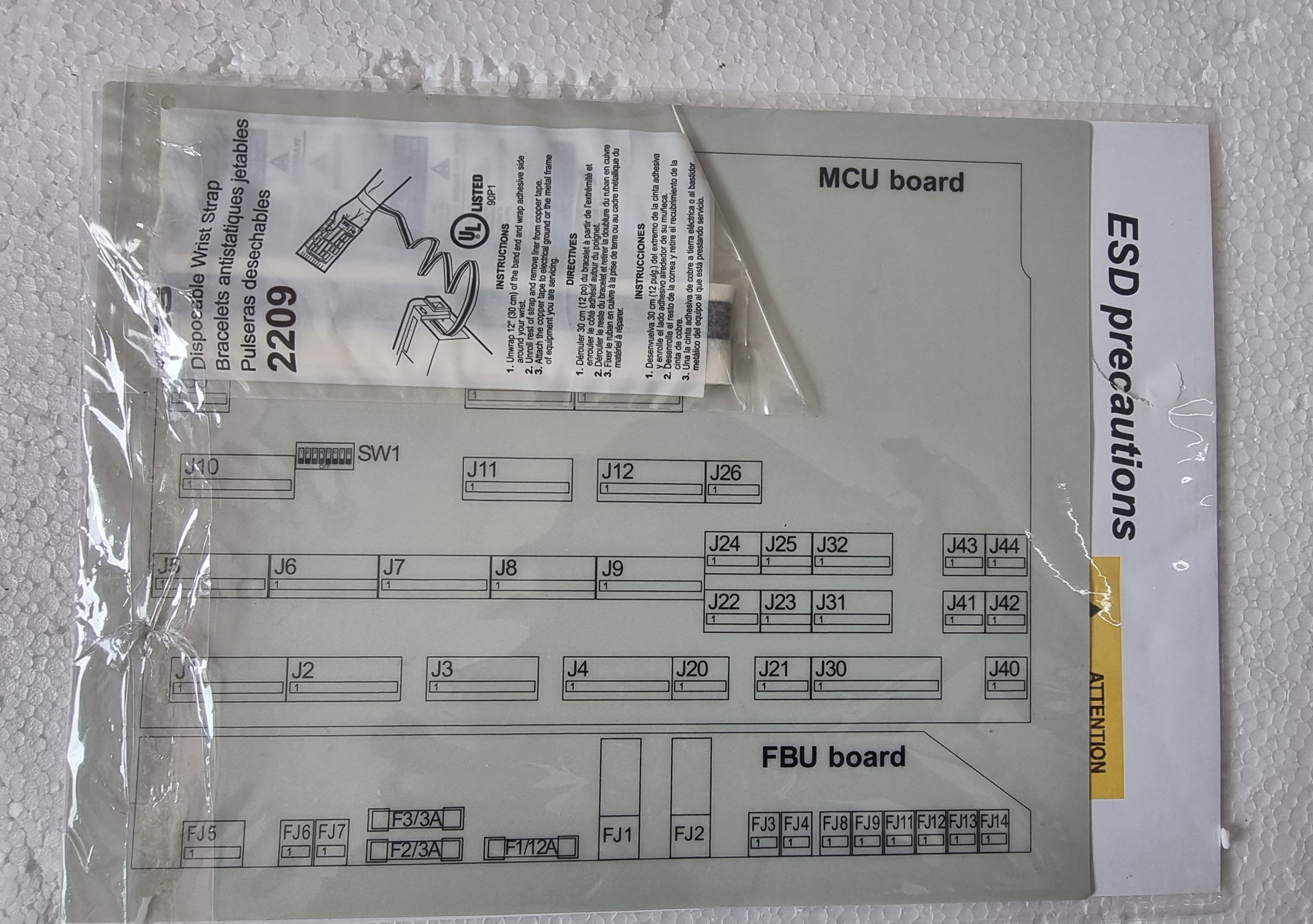

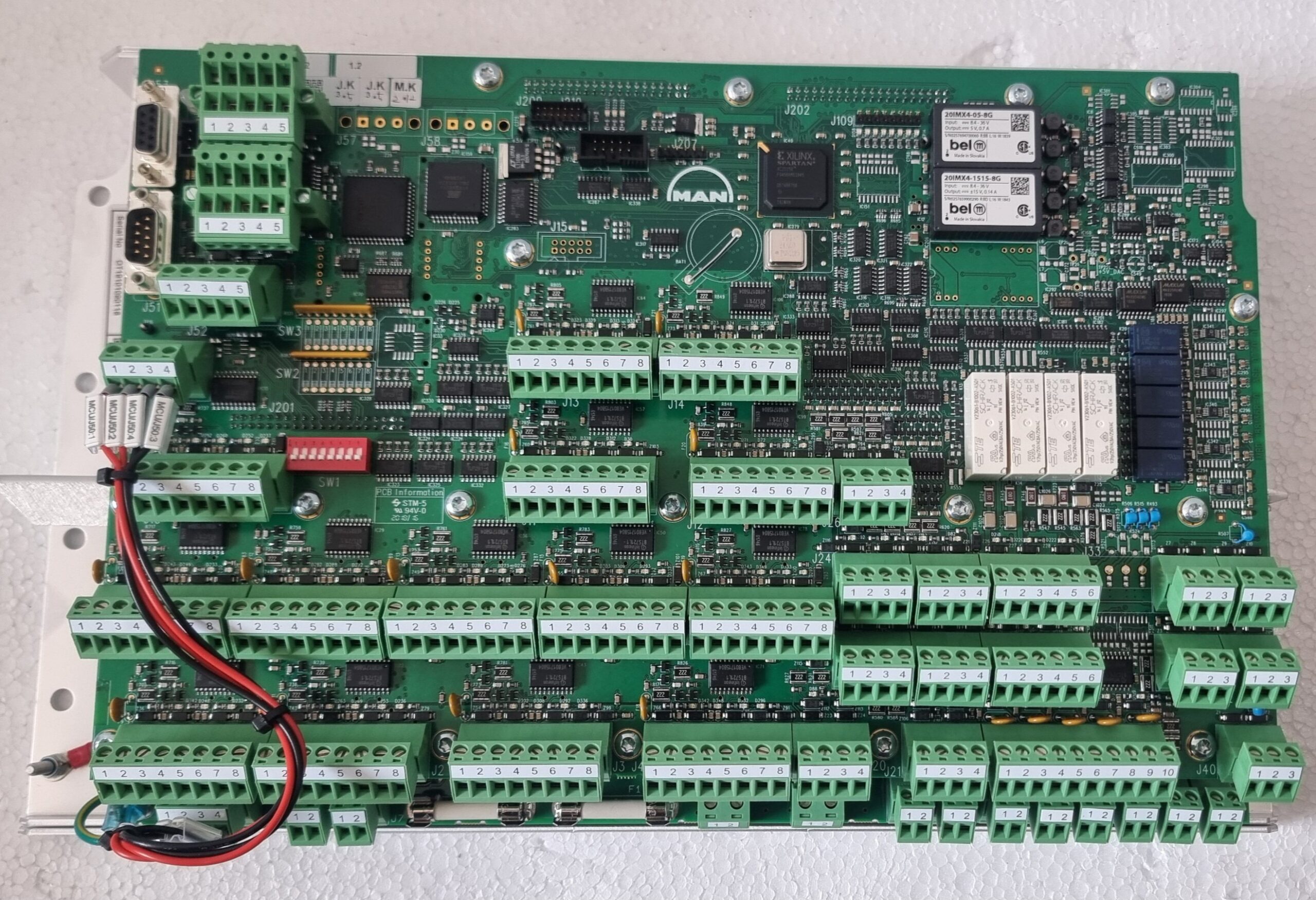

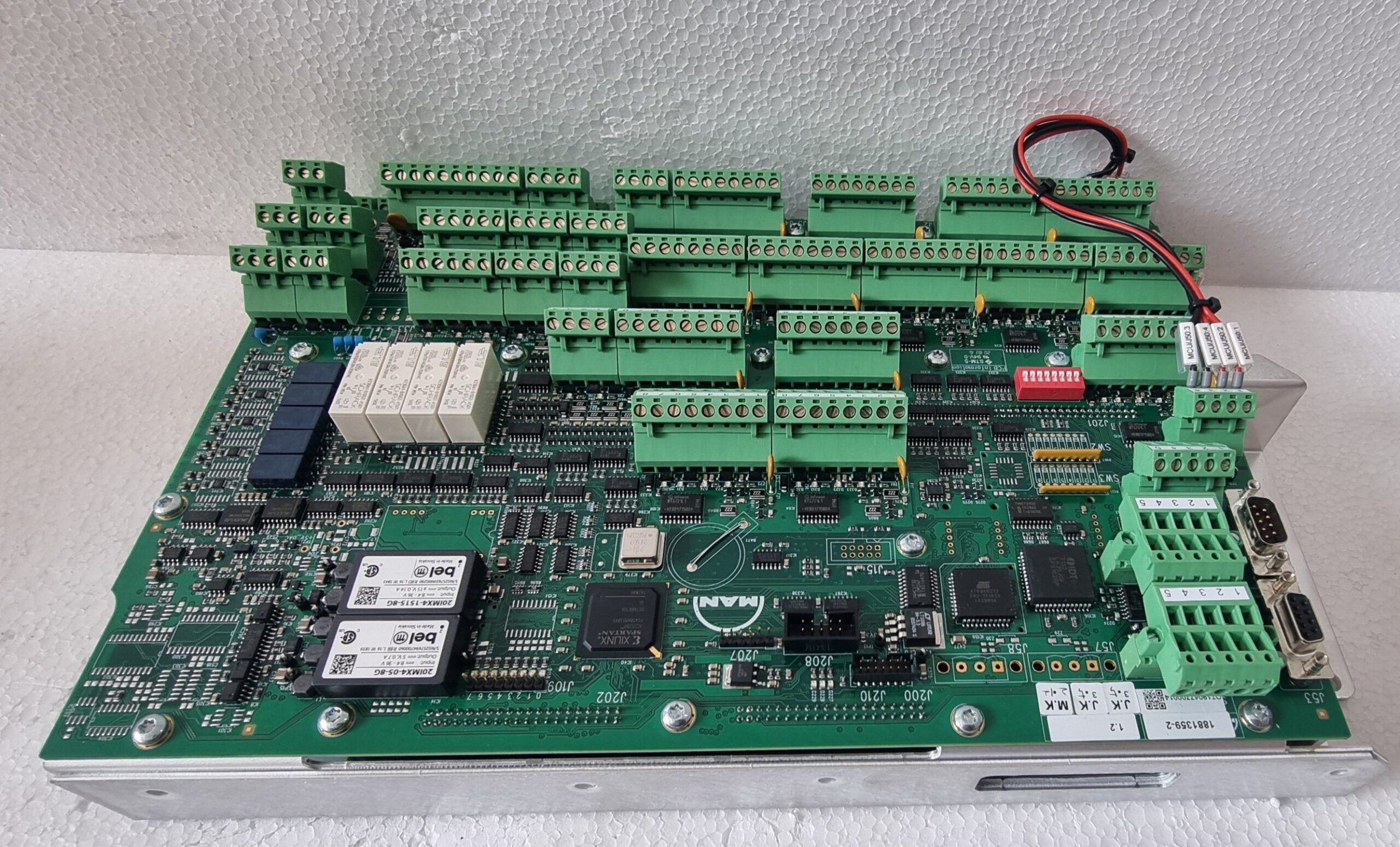

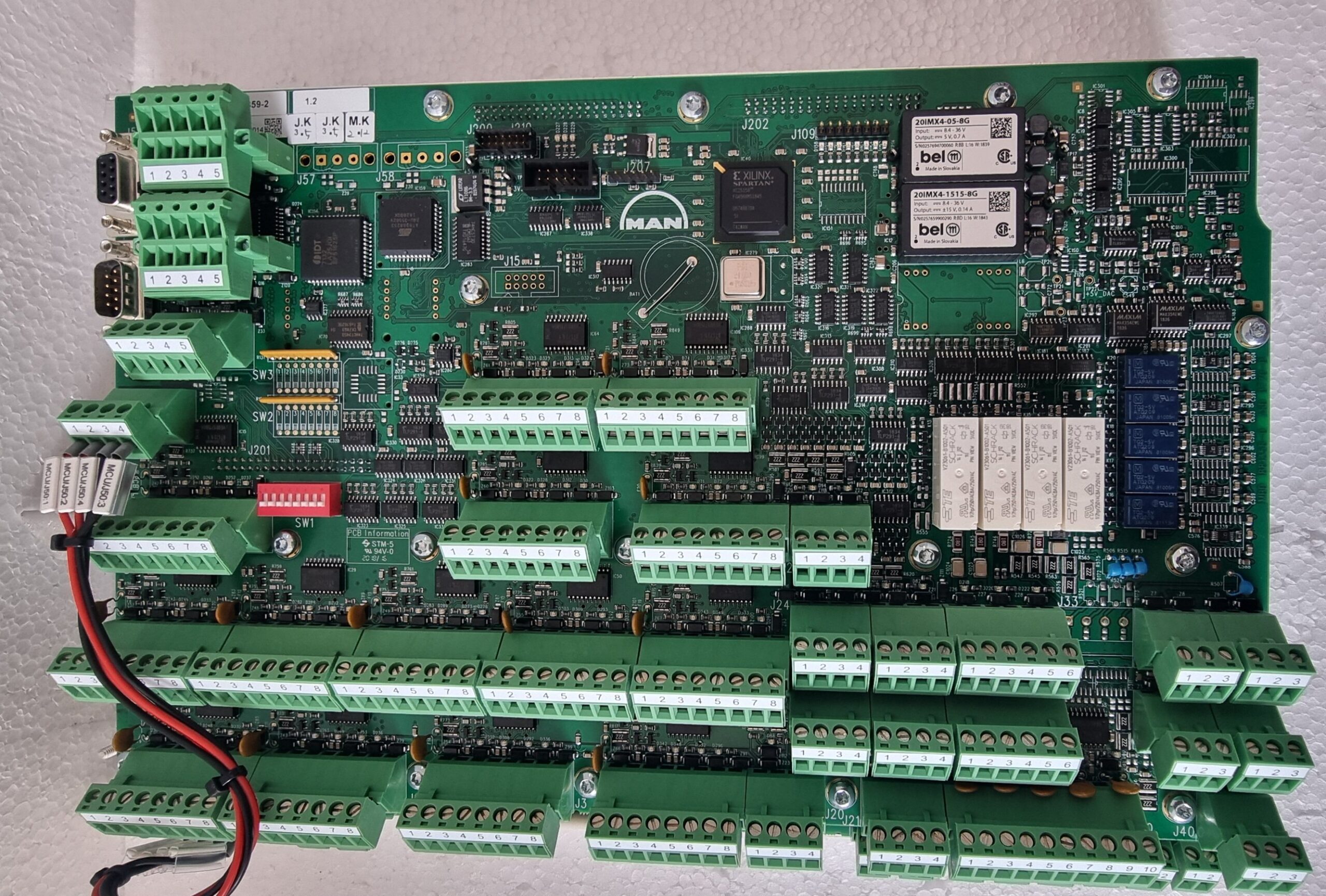

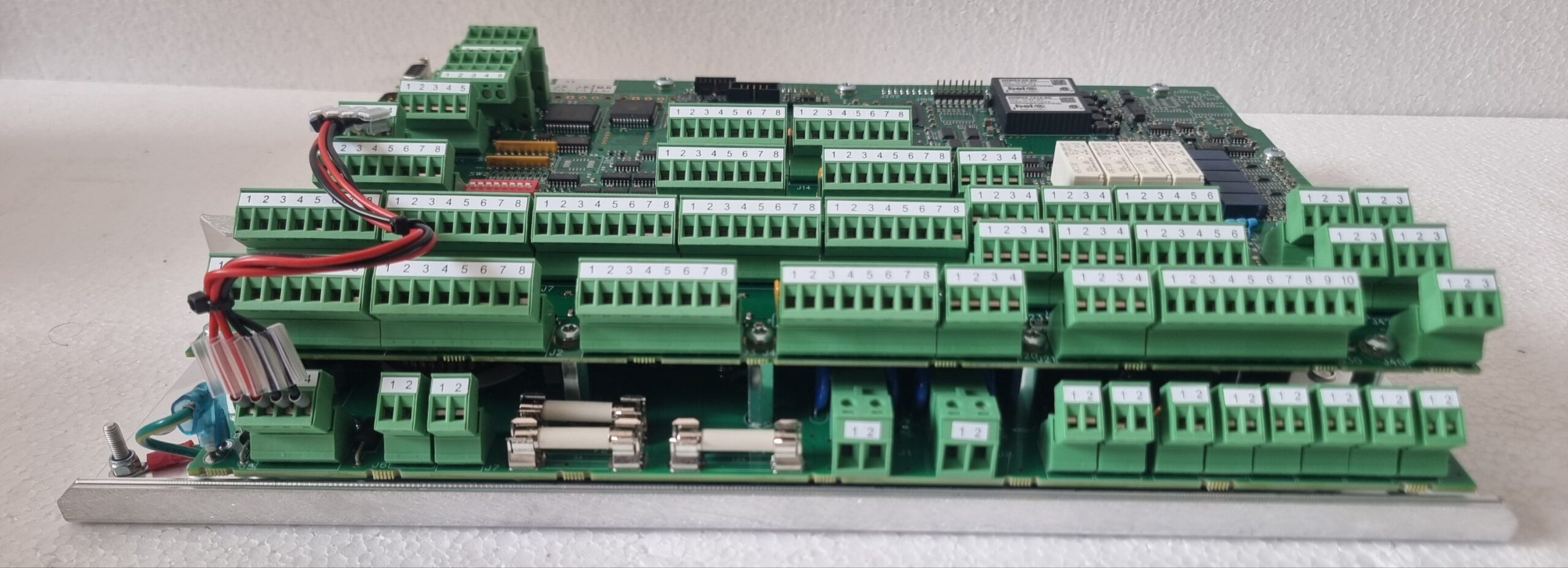

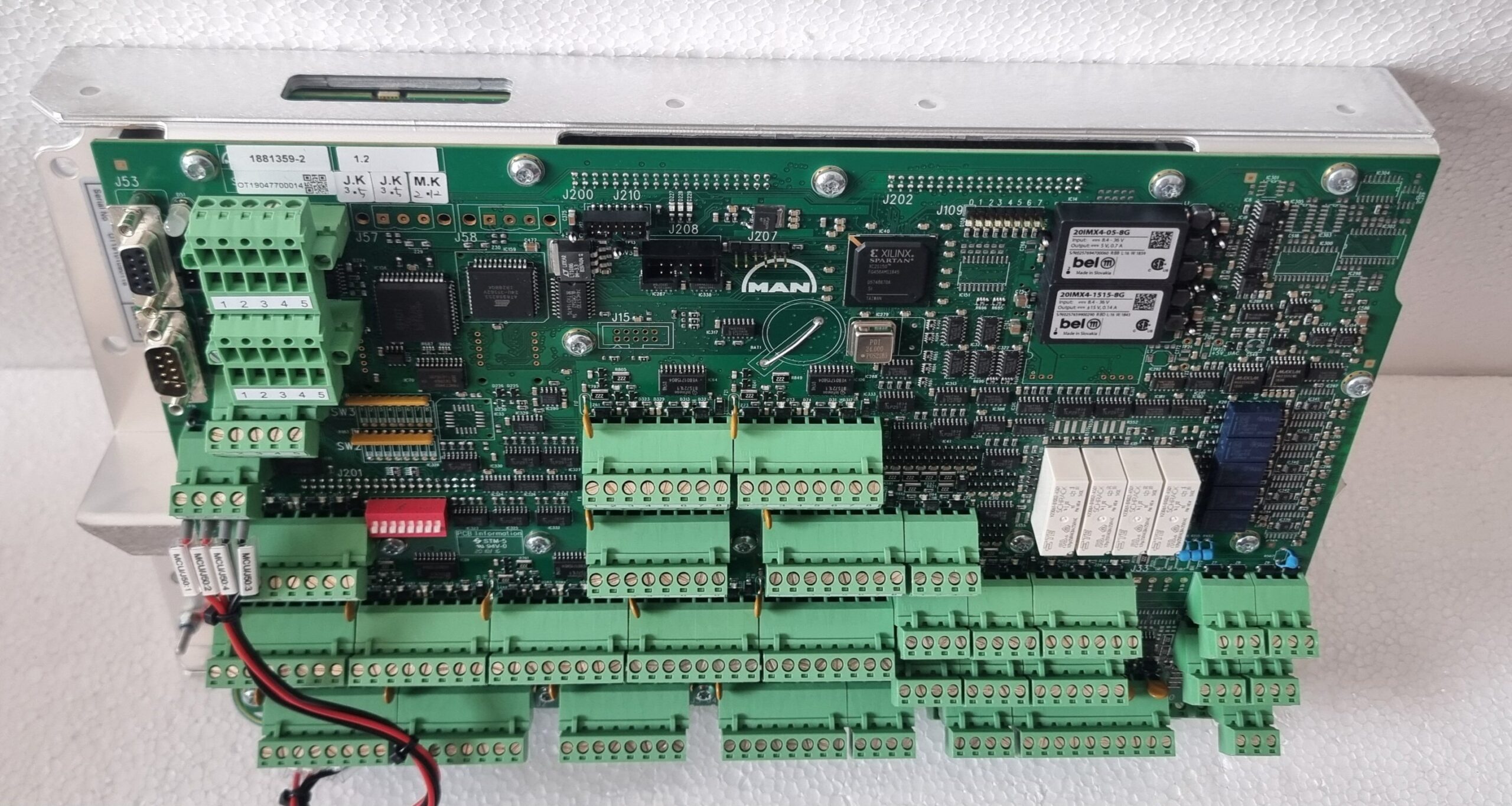

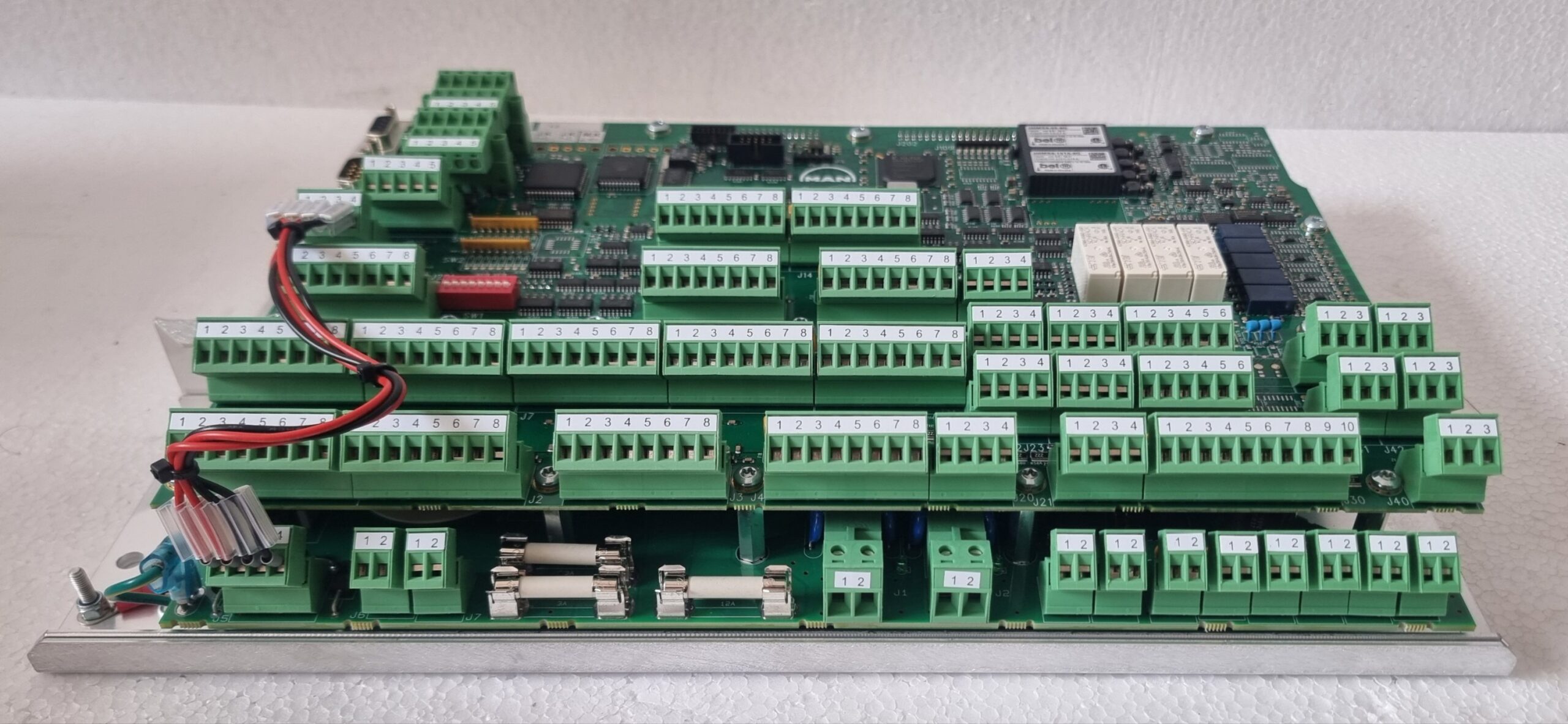

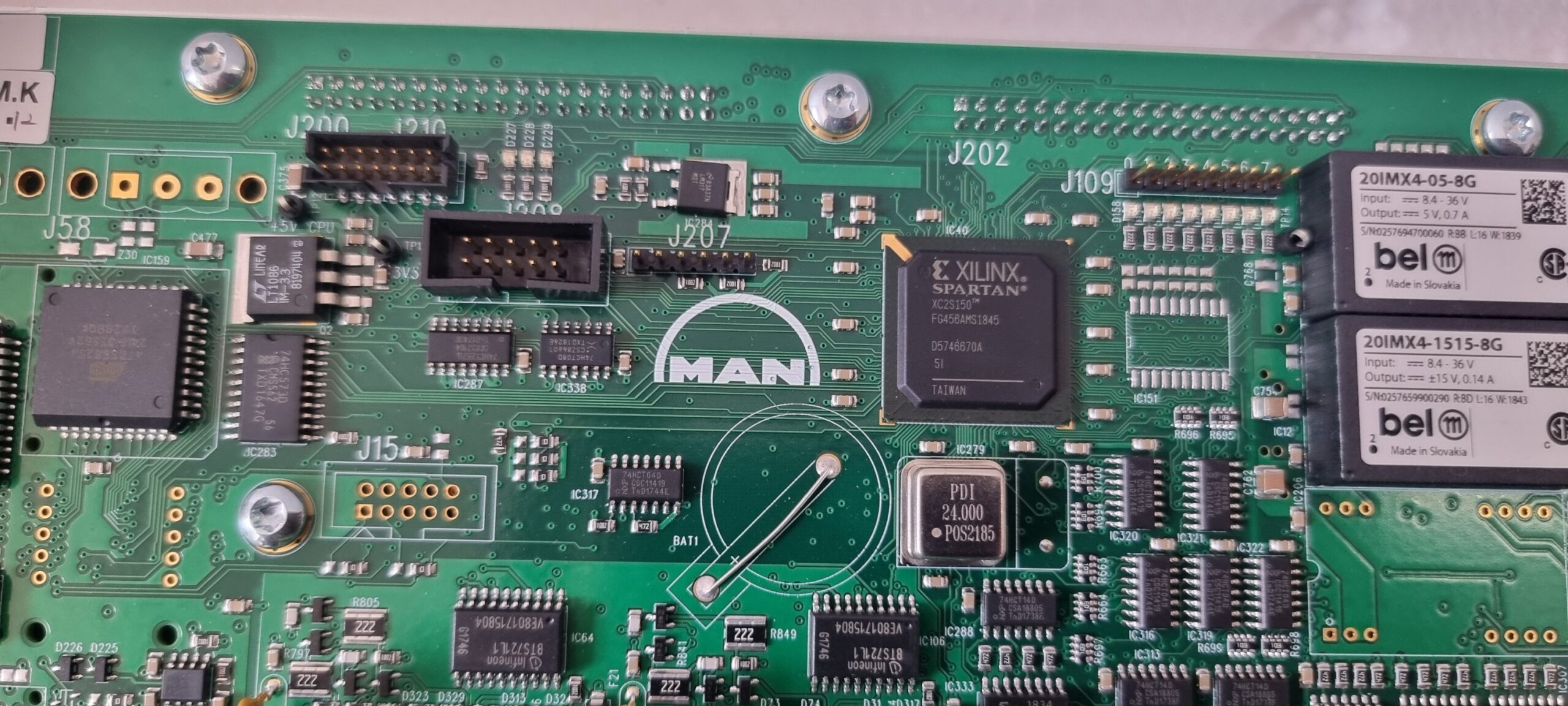

PCB: Stands for Printed Circuit Board. This is the physical board that holds the electronic components (chips, resistors, connectors, etc.) that make up the Master Control Unit.

What is this Part? (Master Control Unit PCB)

The MAN B&W 1881610-7 REV 1.4 is the main computer board for the engine’s control system.

Think of it as the “Brain” or “Central Nervous System” of a modern MAN B&W marine diesel engine. It is a core component of the Engine Control System (ECS) or Fuel Injection Control System.

Its primary functions include:

-

Engine Governing: It precisely controls the engine’s speed (RPM) based on the input from the bridge telegraph (the captain’s command) and the actual measured speed from sensors.

-

Fuel Injection Control: It calculates and commands the exact timing and duration of fuel injection for each cylinder to ensure optimal combustion, efficiency, and power output.

-

Safety and Limitation Functions: It continuously monitors critical engine parameters (temperature, pressure, speed). If any parameter exceeds safe limits, it will automatically reduce engine power or initiate a shutdown to prevent severe damage to the engine.

-

Integration: It communicates with other control systems on the ship, such as the bridge control system, alarm system, and power management system.

Where is it Used?

This specific PCB is installed in the control cabinet or governor cabinet located in the engine control room (ECR) or directly on the engine itself (on newer models with integrated systems). It is the central module that other control units and sensor inputs connect to.

Why is the Revision (REV 1.4) Important?

Using the correct revision is critical. A REV 1.4 board may have different firmware, slightly different circuitry, or use different components than a REV 1.2 or 1.3 board. Installing an incorrect revision could lead to:

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.