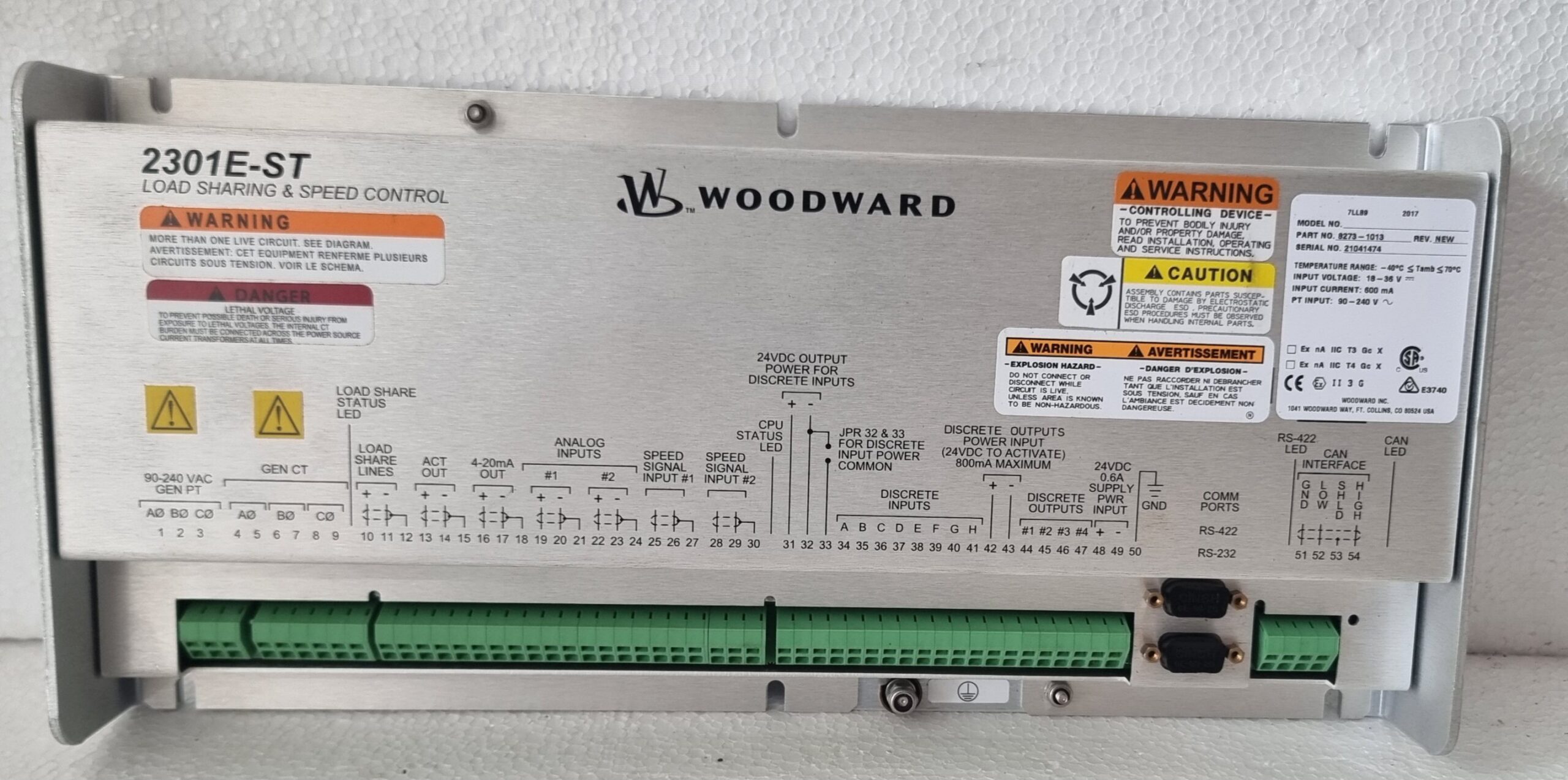

The Woodward 2301E-ST is a sophisticated digital control system designed primarily for governing diesel or gaseous-fueled engines and managing electrical generators. Its core functions are to precisely control the engine’s speed (RPM) and, when generators are connected in parallel, to manage how they share the total electrical load.

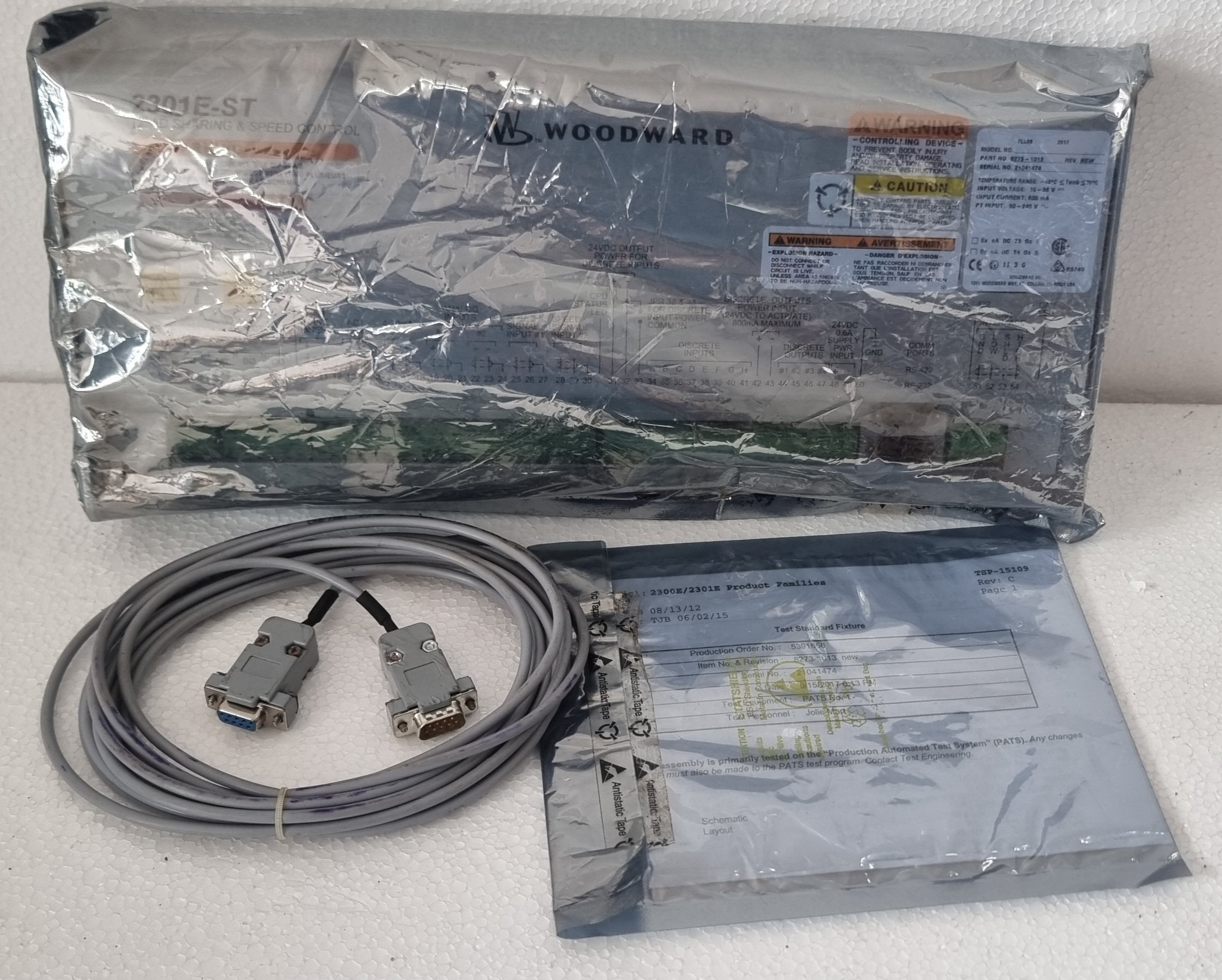

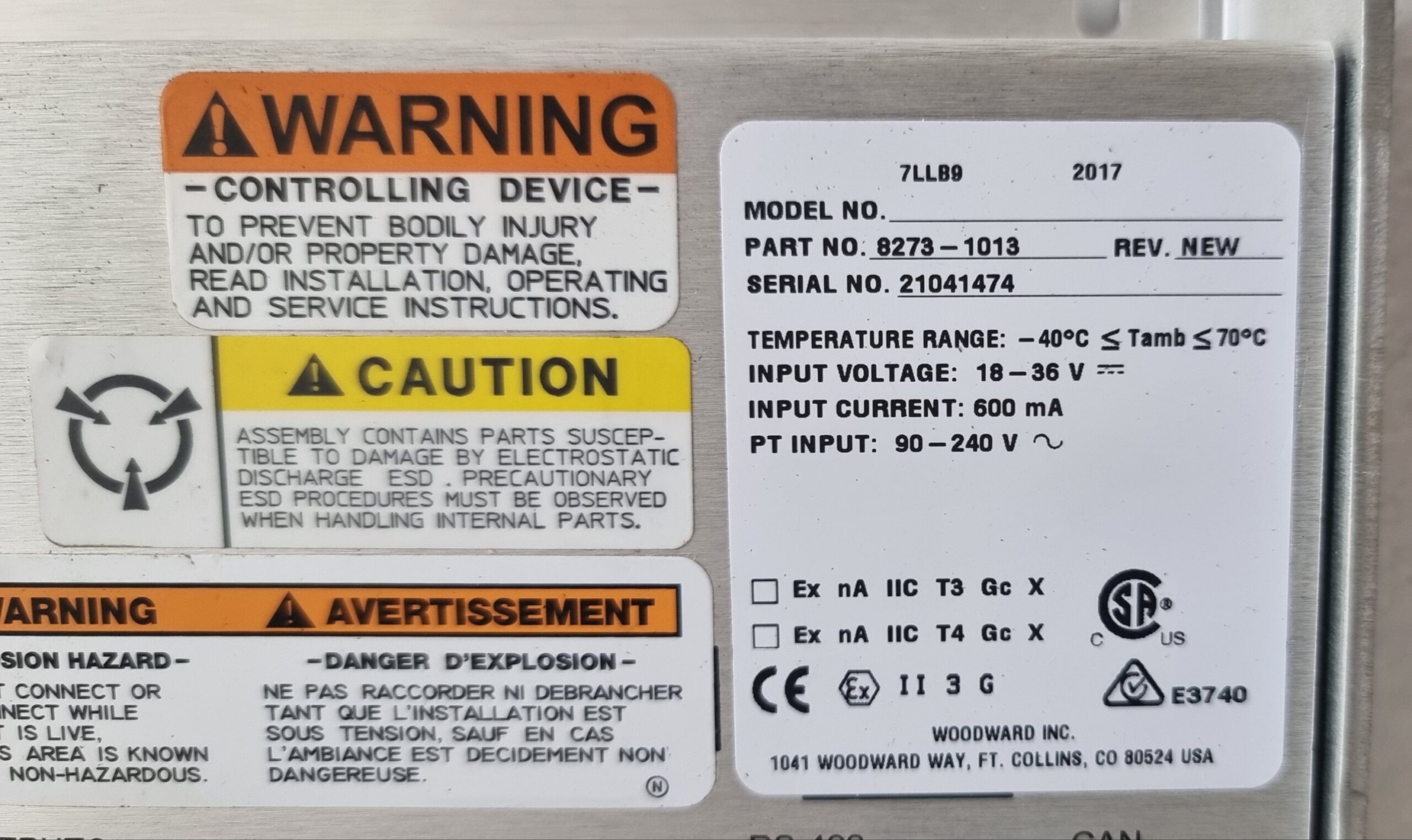

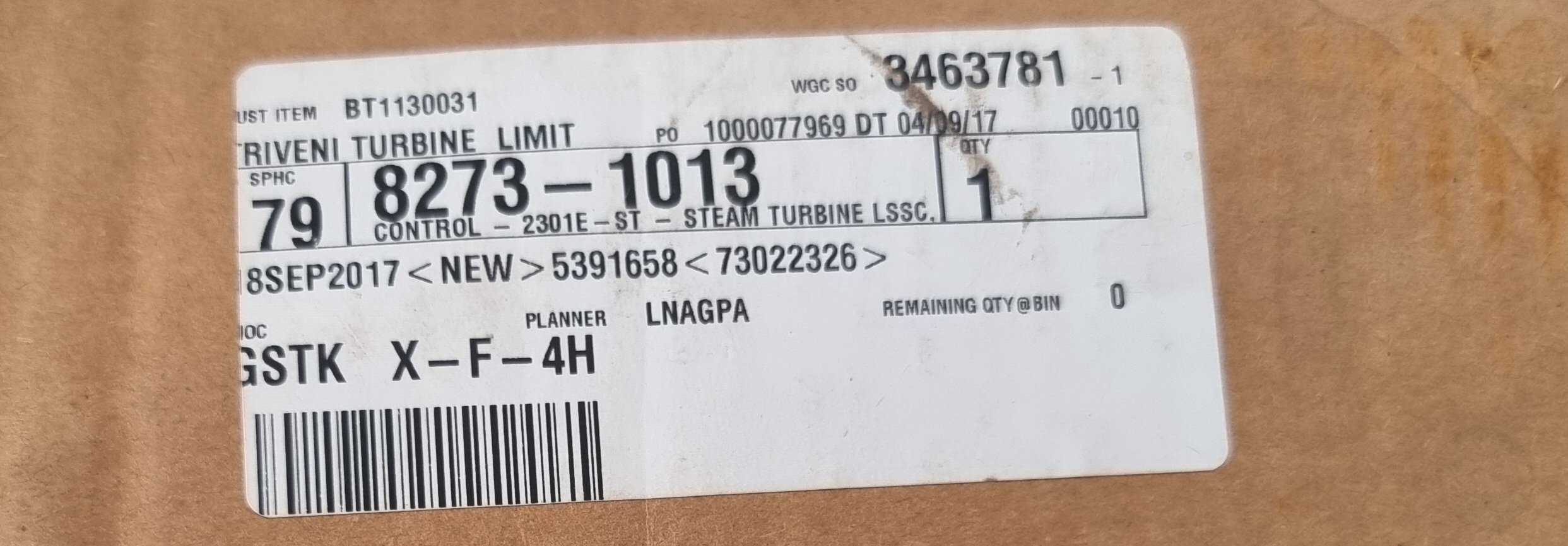

The part number 8273-1013 is the specific Woodward drawing or product number for this unit. “REV NEW” indicates this is the latest revision of the hardware and firmware, meaning it incorporates all the most recent updates and improvements from Woodward.

Key Functions and Features:

-

Speed Control (Governor):

-

Its primary job is to maintain a constant engine speed regardless of changes in load. For example, if a large electrical load (like a big motor starting) is suddenly applied to the generator, the 2301E-ST will instantly signal the engine’s fuel system to increase fuel to maintain the set speed (typically 1800 or 1500 RPM for 60Hz or 50Hz power). It does this using a Proportional-Integral-Derivative (PID) control algorithm for high accuracy.

-

-

Load Sharing (Isochronous Load Control):

-

This is its most critical feature for parallel operations. When multiple generators are running together to power a common electrical bus (a “paralleling genset system”), the 2301E-ST communicates with the controls on the other generators.

-

It ensures that each generator takes its fair share (e.g., 50% of the load for two equally sized units) of the total electrical load. It prevents one generator from being overloaded while another is under-loaded.

-

-

Digital and Programmable:

-

Unlike old mechanical governors, this is a fully digital electronic control. It can be easily configured and tuned using a Windows-based software tool (ProAct® or ToolKit) connected via a front-port communication cable.

-

Parameters like speed setpoints, gain settings, ramp rates, and load sharing characteristics can be adjusted to match the specific engine and application.

-

-

Protection and Metering:

-

The unit monitors critical engine and generator parameters (like overspeed, underfrequency, low oil pressure, high coolant temperature) and can shut down the engine or generate alarms to protect it from damage.

-

It can also provide data for display, such as engine speed, generator frequency, and output power (kW).

-

-

Synchronizing:

-

It often works in tandem with a separate automatic synchronizer module to match the voltage, frequency, and phase angle of the generator to the bus before closing the circuit breaker to connect them.

-

Typical Applications:

This controller is used in demanding applications where reliable and precise power generation is critical:

-

Power Generation Plants: Standby, prime power, and continuous duty generator sets.

-

Marine Applications: For shipboard power generation (on vessels with diesel-electric propulsion or auxiliary power).

-

Oil & Gas Industry: Powering drilling rigs, pipelines, and remote facilities.

-

Data Centers: Providing critical backup power.

-

Industrial Facilities: For cogeneration (Combined Heat and Power – CHP) and peak shaving.

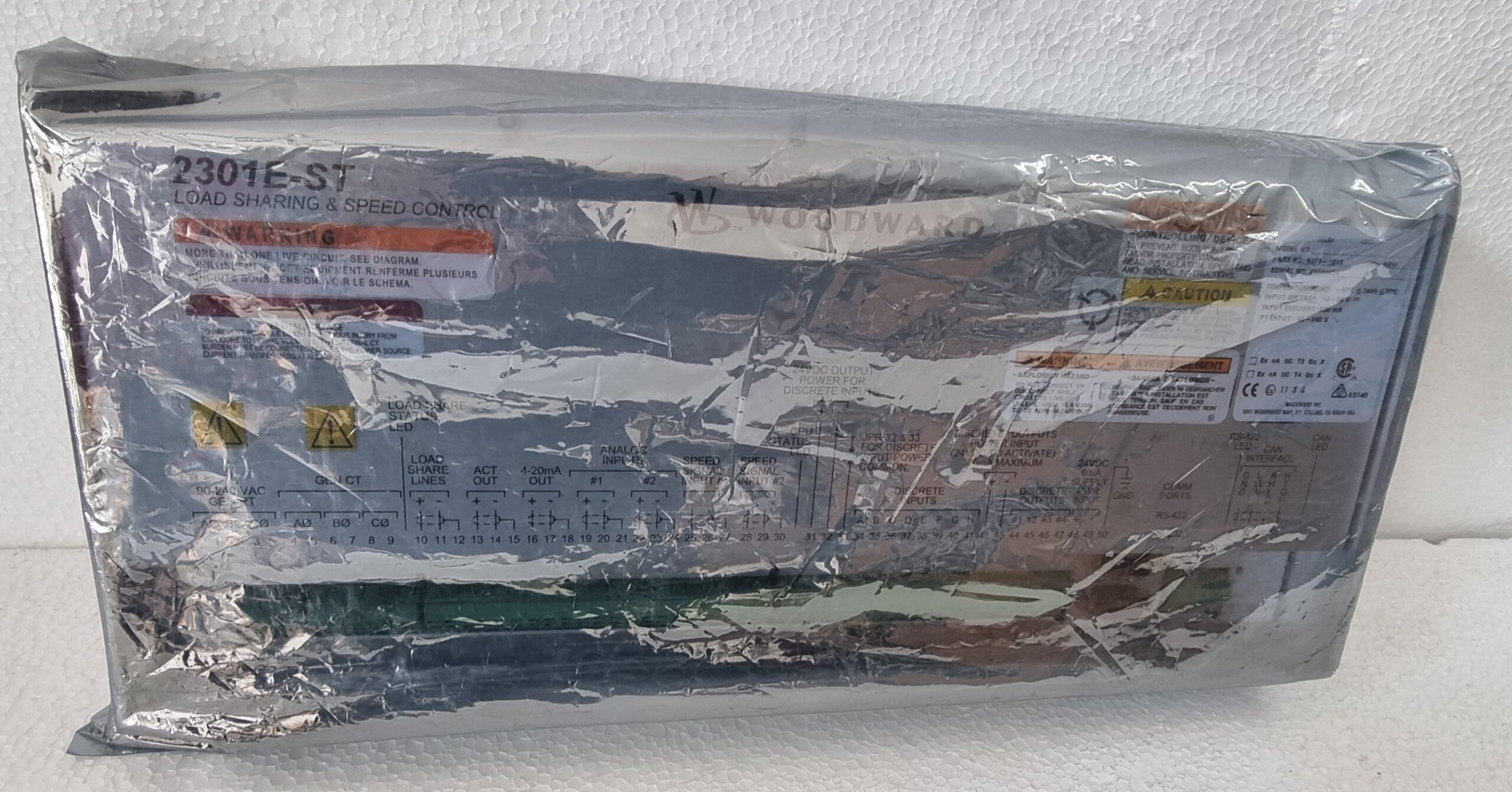

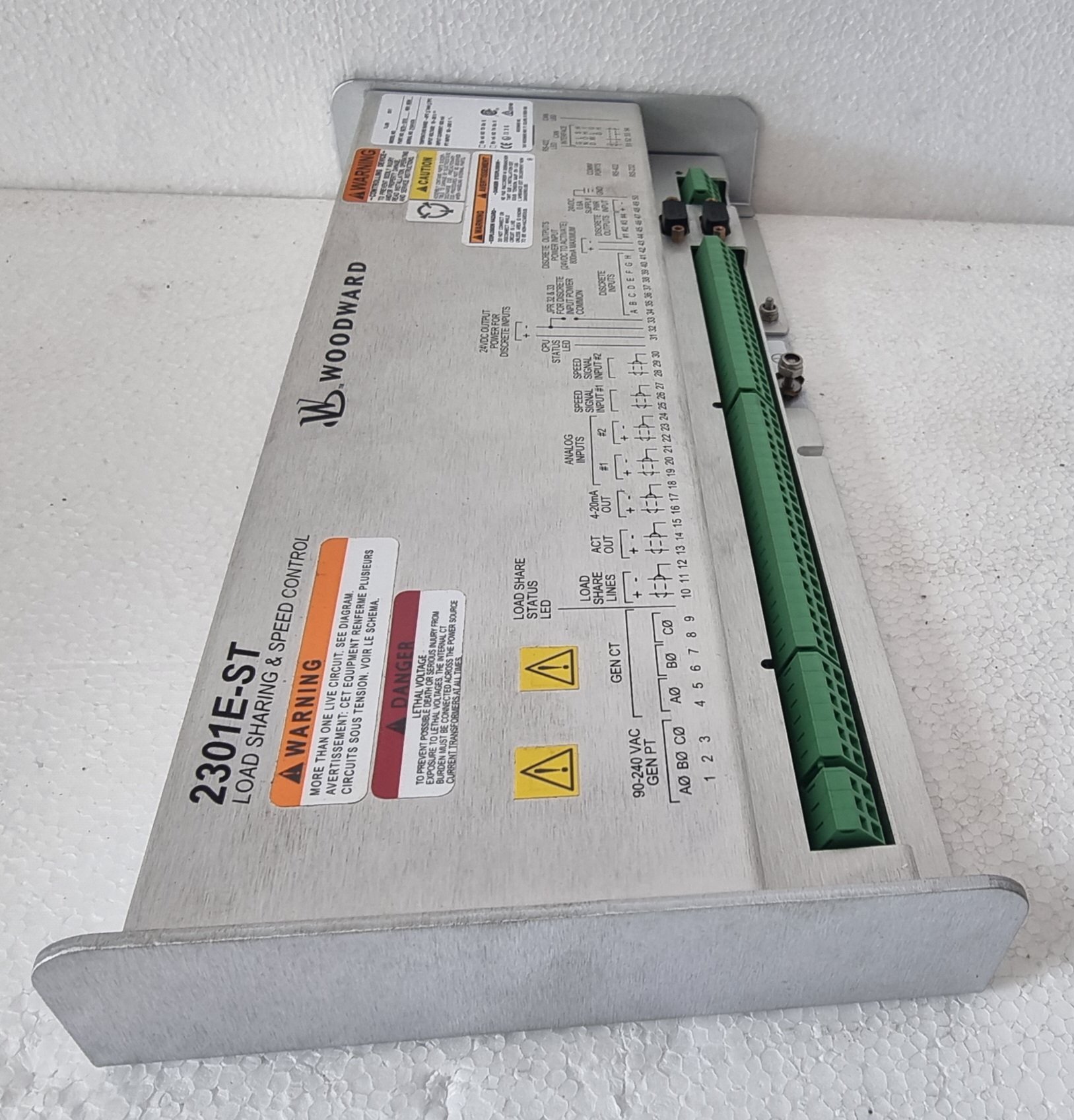

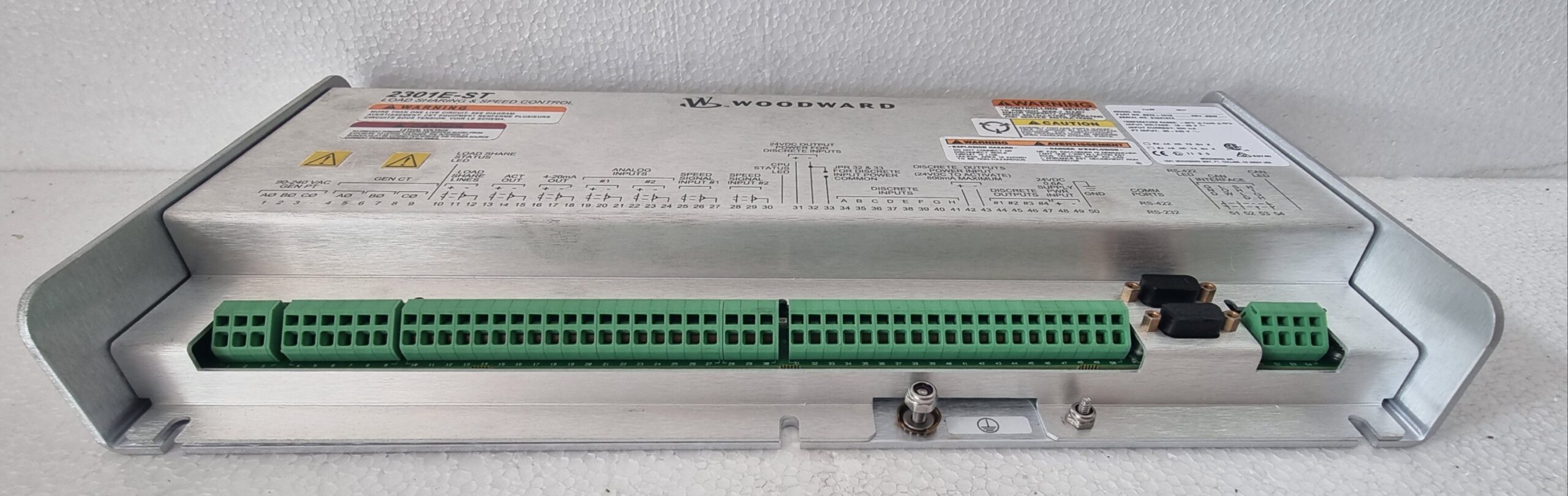

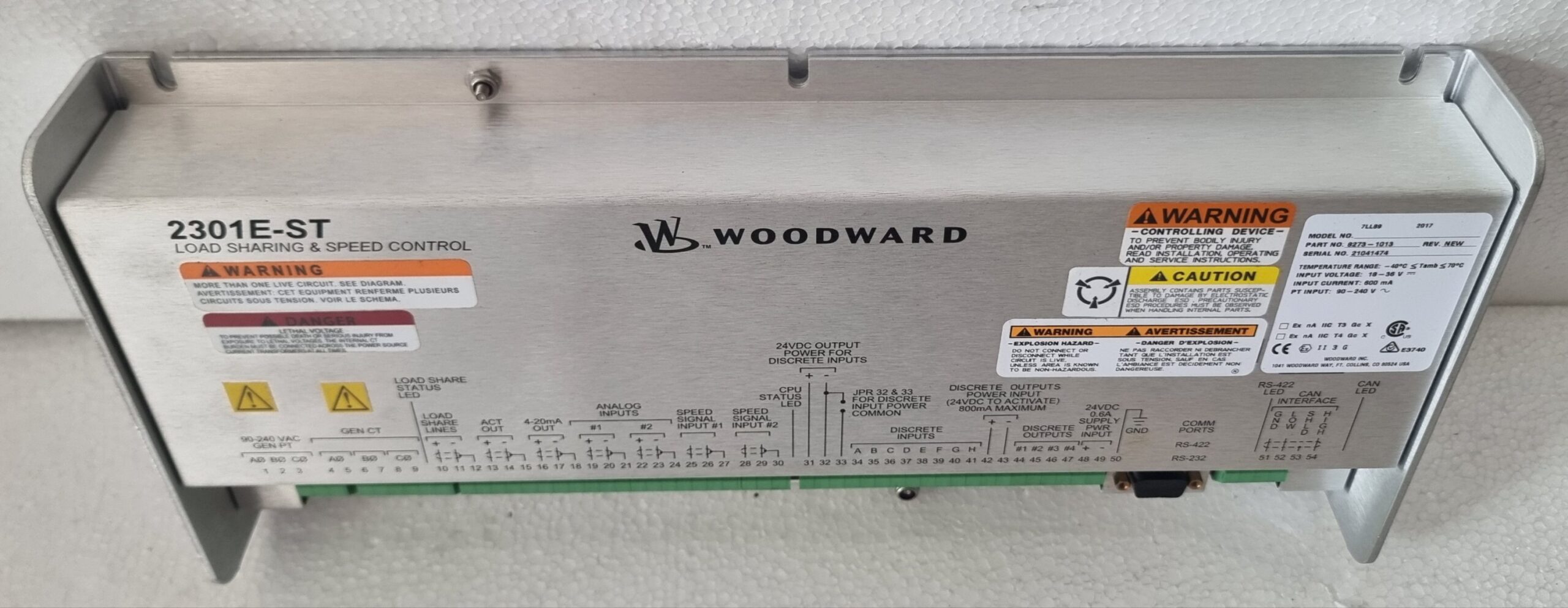

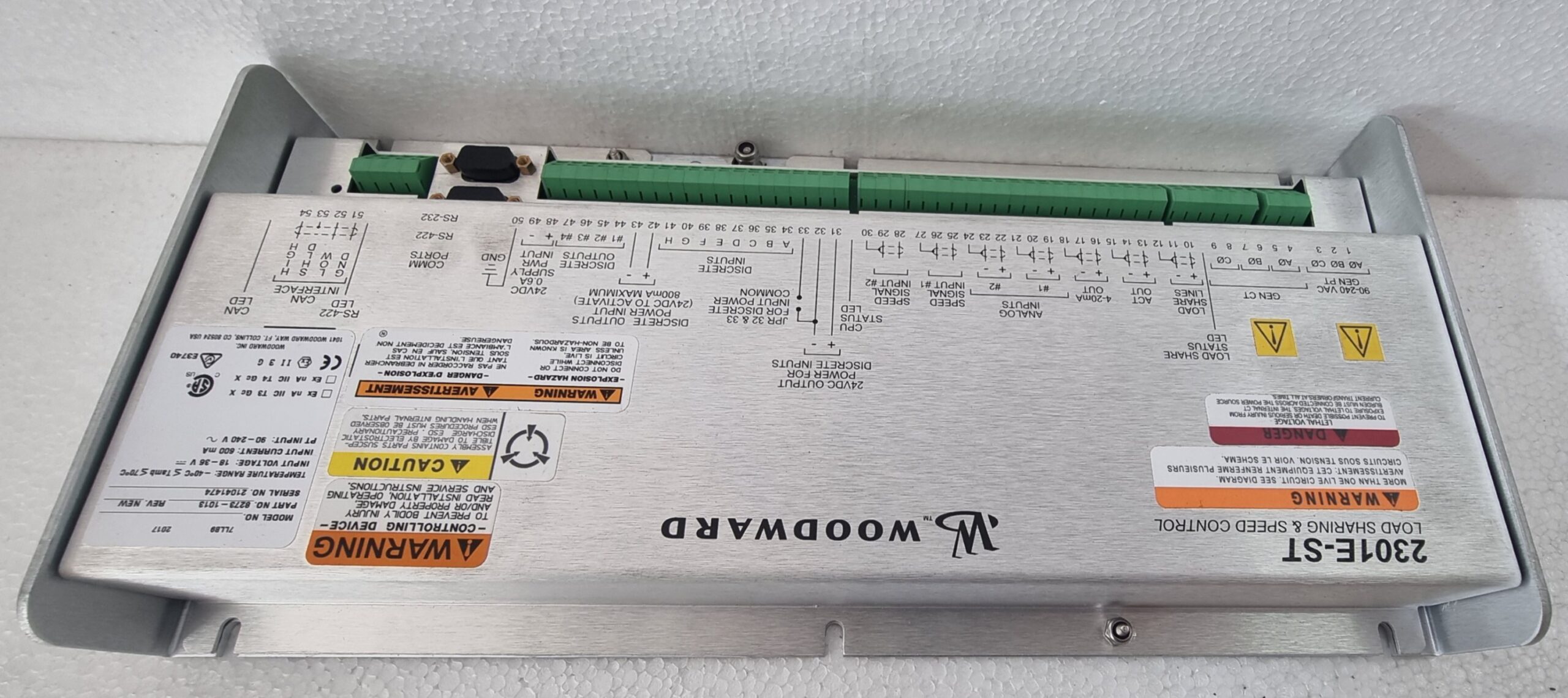

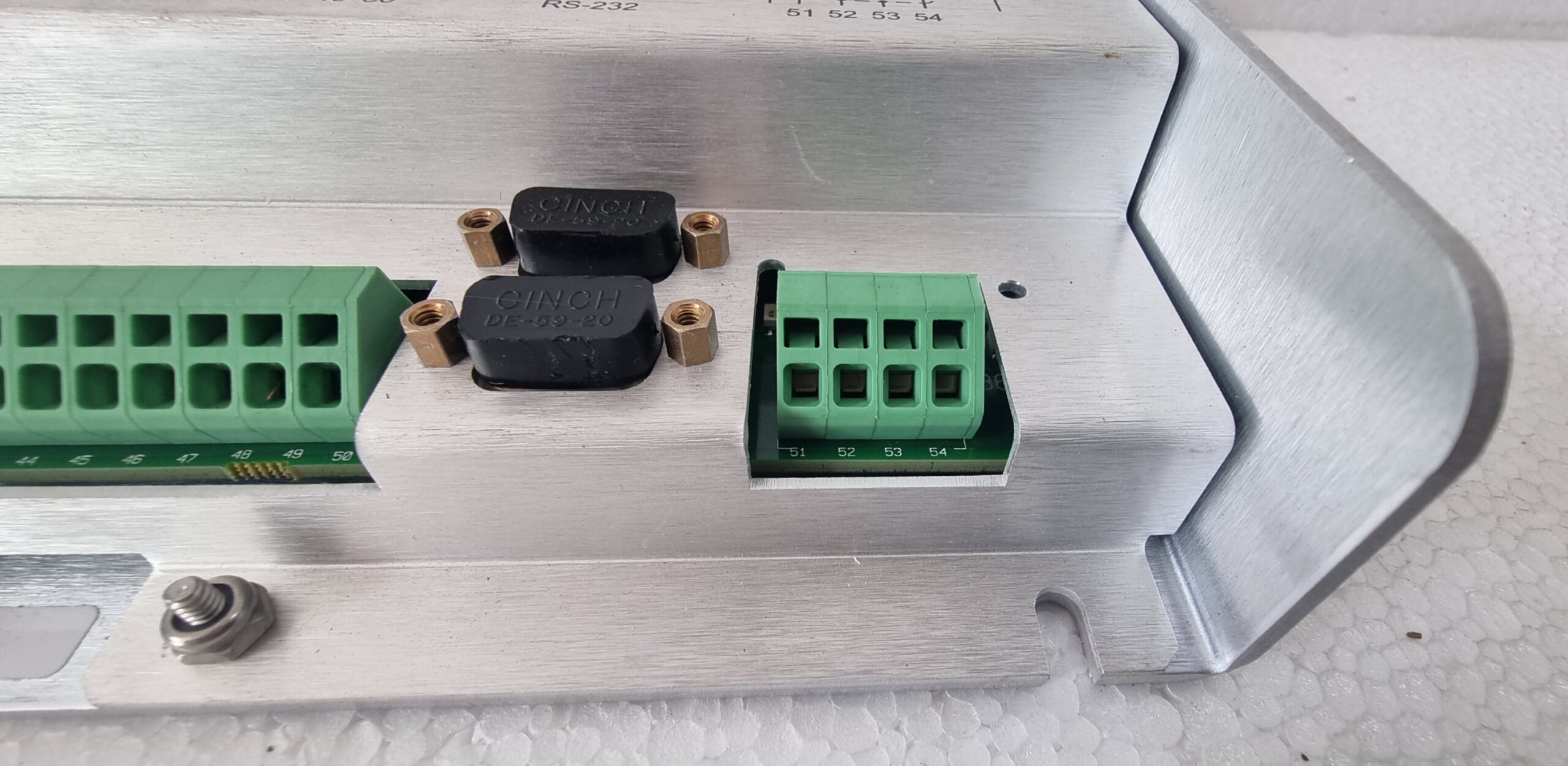

Physical Description:

The unit is a sturdy electronic module housed in a metal case designed to be mounted in a control panel. It will have a multi-pin electrical connector on the back for wiring to sensors, actuators, and other controls, and a front display with buttons or a communication port for setup.

Reviews

There are no reviews yet.