-

WOODWARD: The manufacturer. Woodward, Inc. is an American company and a global leader in the design, manufacture, and service of control systems and components for aircraft and industrial engines and turbines.

-

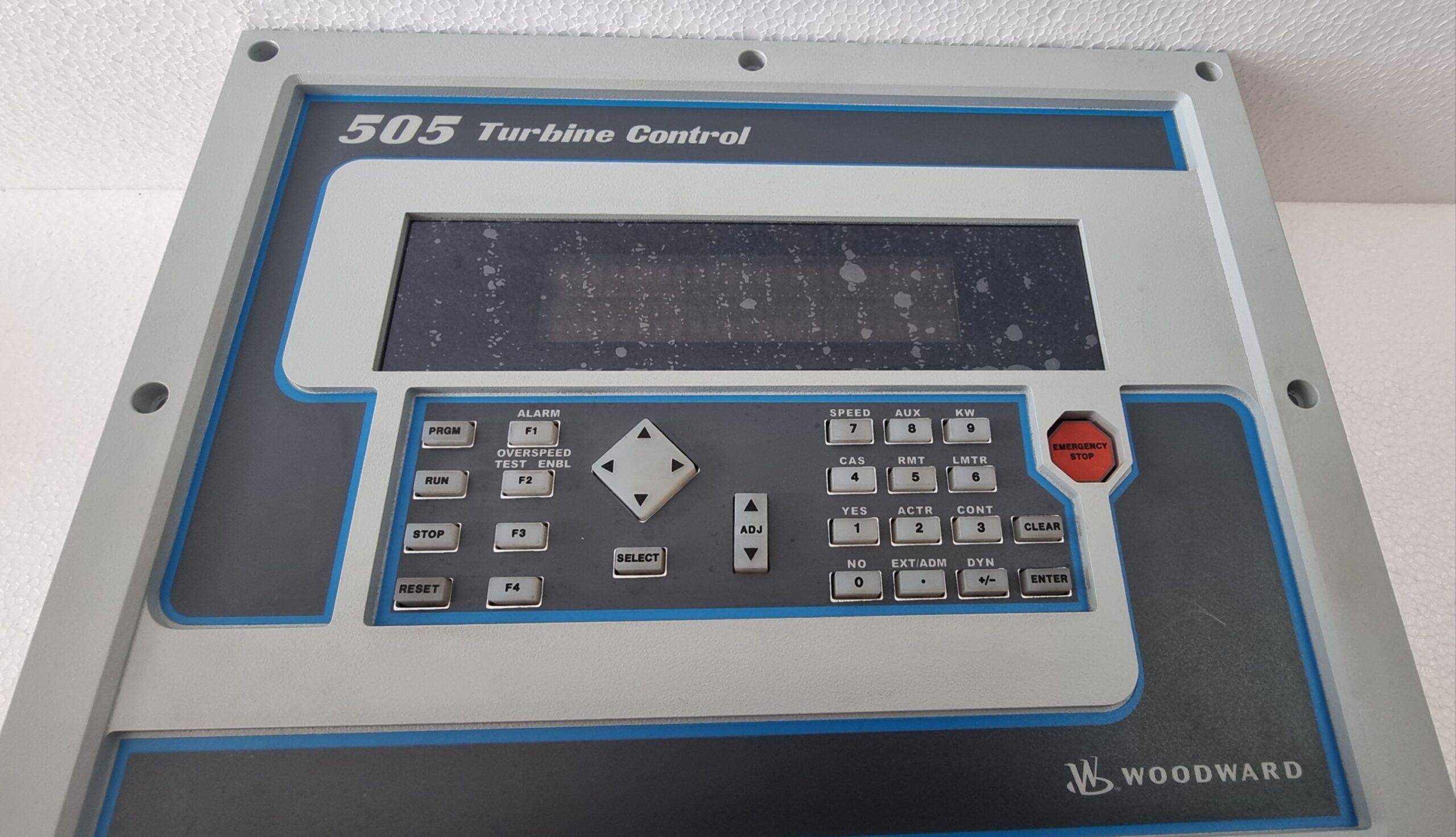

505: This is the Model Number. The Woodward 505 is a legendary and extremely popular digital control system specifically designed for controlling mechanical-hydraulic steam turbines and smaller gas turbines. It is a standalone governor.

-

TURBINE CONTROL GOVERNOR: This is the functional description. This unit is responsible for starting, stopping, controlling speed, and regulating load on a turbine. It replaces older mechanical governors with precise digital control.

-

PART NUMBER : 9907-164: This is the unique part number for this specific control unit. The “9907” prefix is common for the 505 product line.

-

REV :T: This stands for Revision T. This indicates a specific hardware and/or software revision level for this unit. Revisions incorporate improvements, bug fixes, or new features. Matching the revision is often important for compatibility and operation.

-

24VDC: This specifies the required operating voltage. This particular unit is designed to be powered by a 24 Volt Direct Current power supply, which is a very common standard in industrial and marine control panels.

What is this Part? (Woodward 505 Governor)

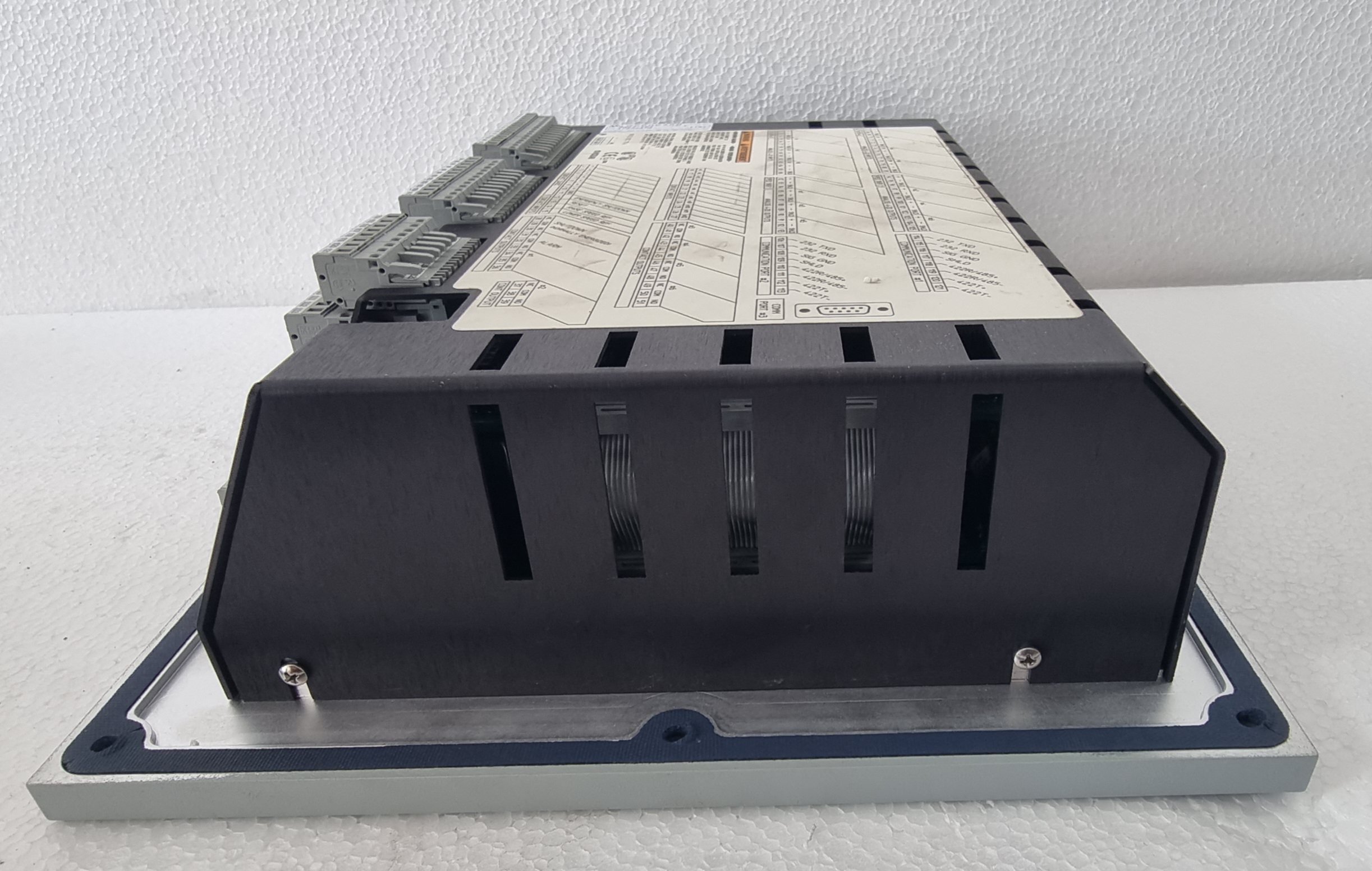

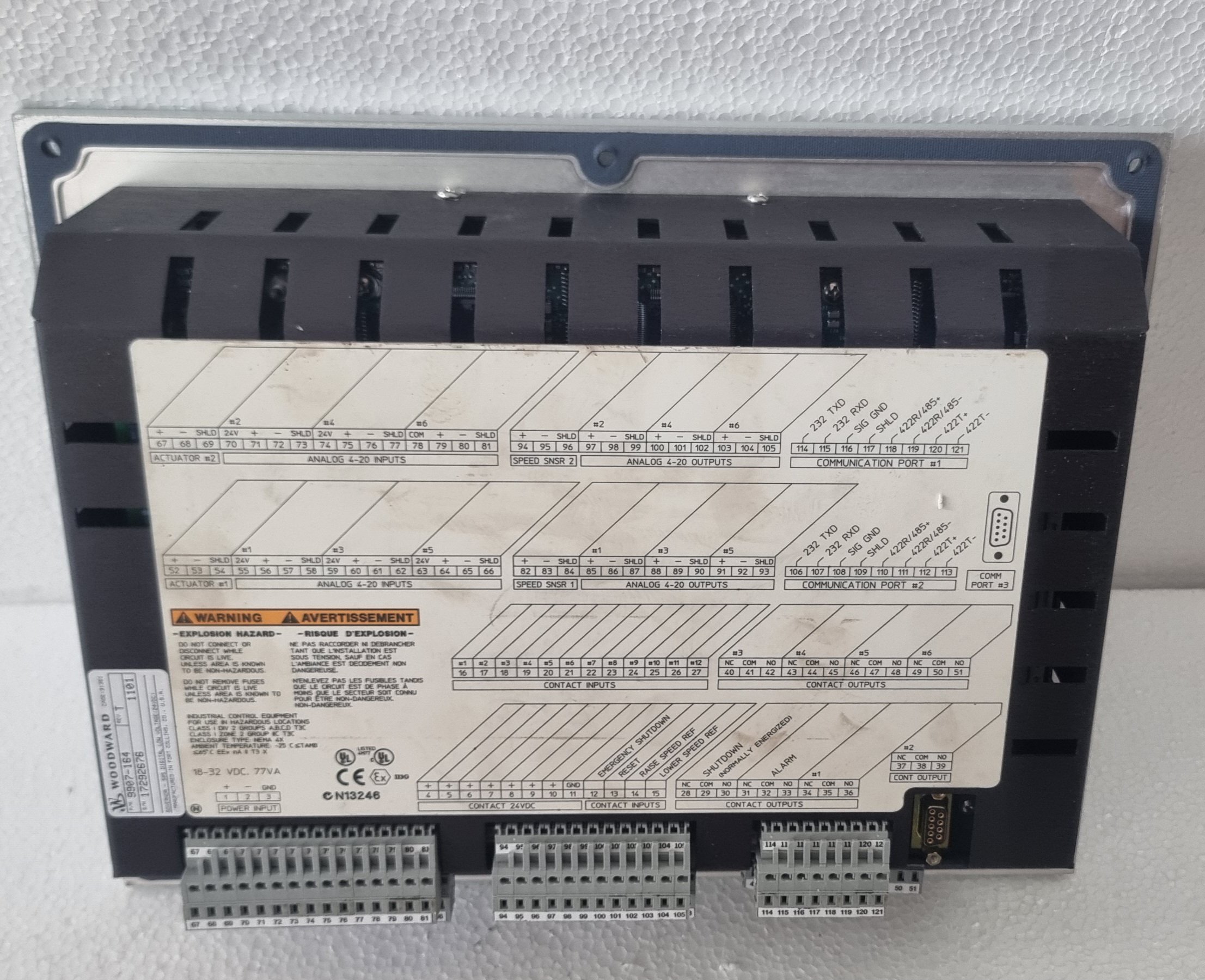

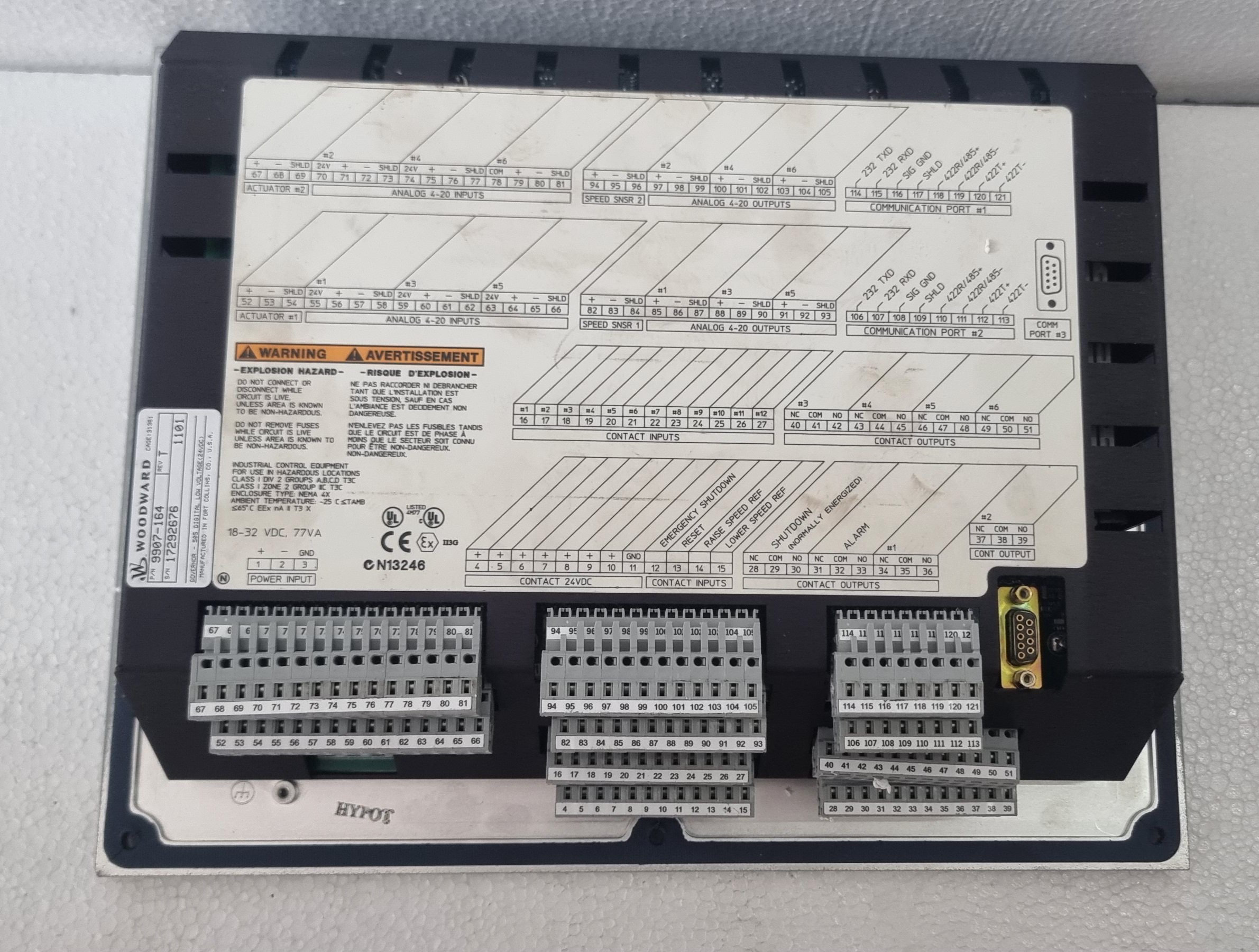

The Woodward 505 (P/N 9907-164, Rev T) is a complete, pre-programmed digital control system housed in a single chassis. It is not just a PCB; it’s an integrated control unit with a built-in keypad and display.

Its primary functions are to act as the “brain” for a turbine, providing:

-

Speed Control: Precisely regulates the turbine’s rotational speed (RPM) to a setpoint, crucial for generators and compressors that need to run at constant speed.

-

Load Control: For generator drives, it can control the power output (in MW) of the turbine-generator set, responding to changes in the electrical grid’s demand.

-

Startup/Shutdown Sequencing: Automates the critical process of safely ramping the turbine up to speed and bringing it back down to a stop.

-

Process Control: Can be configured to control other parameters like pressure or flow (common in compressor applications).

-

Protection: Continuously monitors turbine conditions (vibration, temperature, overspeed) and will initiate alarms, runbacks, or trips to safely shut down the turbine if dangerous conditions arise to prevent catastrophic damage.

Where is it Used?

The Woodward 505 is ubiquitous in industries that use small to medium-sized turbines, such as:

-

Power Generation: Driving generators in refineries, chemical plants, paper mills, and remote locations (often called “gen-sets”).

-

Oil & Gas: Driving compressors for gas pipelines and gas lift applications, and pumps for refinery processes.

-

Marine: Sometimes used for auxiliary power turbines or smaller main propulsion systems.

It is typically installed in the control room or in a cabinet near the turbine skid.

Key Features of the 505:

-

Standalone Unit: It integrates the controller, human interface (keypad/display), and I/O (Input/Output) points into one box.

-

User-Programmable: While it comes pre-configured, engineers can program setpoints, control parameters, and start sequences directly through the front keypad.

-

Robust and Reliable: Known for its durability in harsh industrial environments.

Reviews

There are no reviews yet.